Our dock levellers are the most efficient solution and can be manufactured to your specific requirements. Loading Systems has been manufacturing dock equipment for more than 50 years, this experience allowed us to design trustworthy, modular and durable dock levellers. We supply high-quality service for each dock leveller to help you reduce your operational costs and guarantee your employees a safe working environment.

- Durable, long lifespan

- Low maintenance

- Optimum safety

- User-friendly

- Energy efficient

Which dock leveller do I need?

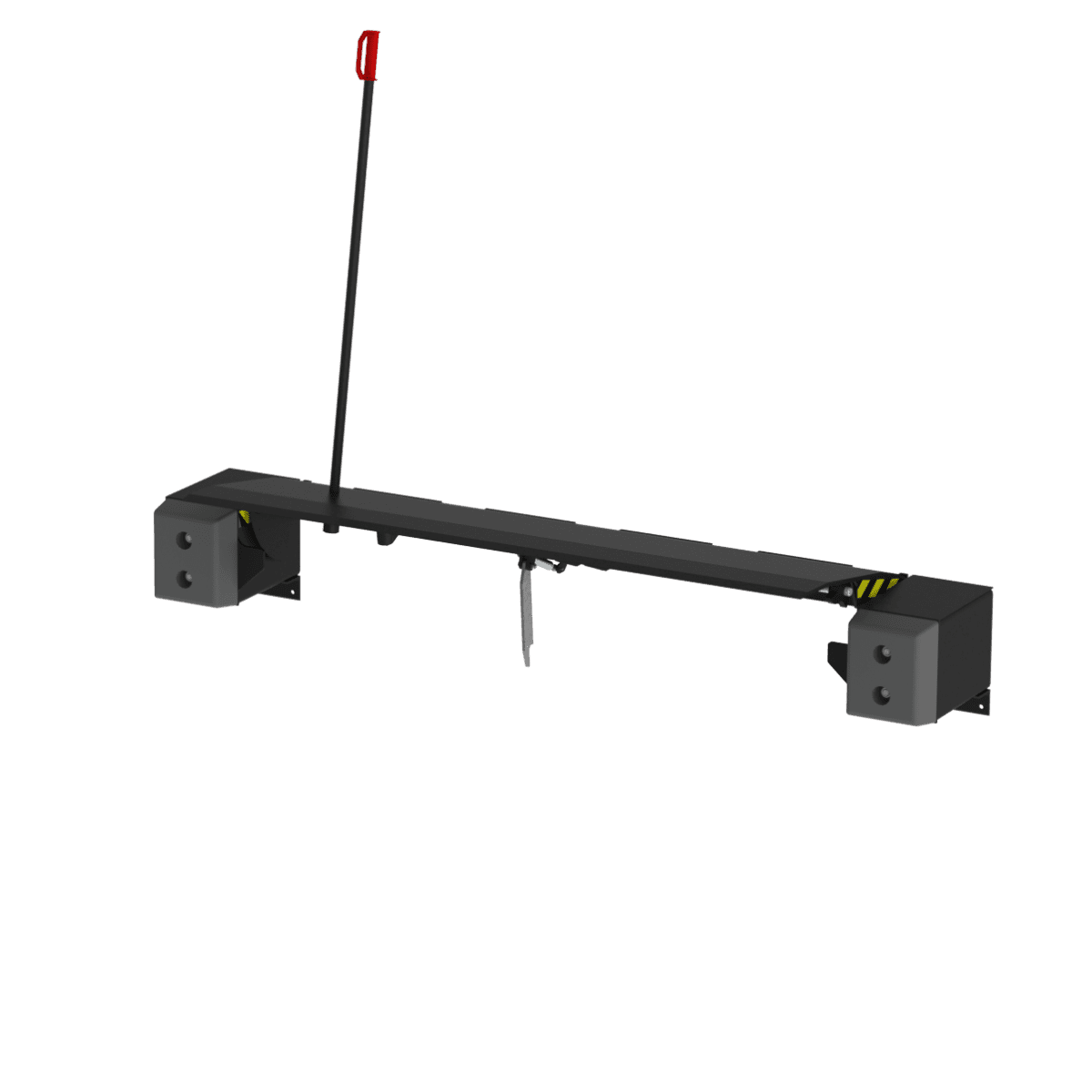

Swing lip dock leveller

Appropriate for most warehousing sites where standard size vehicles operate.

Combi dock leveller

Suitable for situations where trailers ànd delivery vans are loaded and unloaded.

Manual dock leveller

Mainly used in situations which do not facilitate a traditional dock leveller.

Learn more about our dock leveller program

Dock levellers from Loading Systems

Loading Systems can provide bespoke solutions tailored to the customer’s specific needs. No project is too large or too small as we provide solutions for large distribution centres, small warehouses with a single loading bay, double-deck trailers or standard vehicles. We can advise and supply you with solutions for new build or refurbishment projects.

We have a solution for most loading bay applications. Our comprehensive product portfolio and range of options are designed to improve ease of use, safety, and integration with other products or systems typically associated with loading bay activity. Naturally, our products and solutions are designed to be incorporated into the architectural aspects of the building.

We have more than 50 years experience of providing products and solutions to all market sectors including but not limited to logistics, material handling, storage, food manufacturing, cold storage, transport, construction, industry and government.

A dock leveller with countless possibilities

Our dock levellers are available as hydraulic, including extendable or telescopic lip, in a various range of dimensions, capacities, or built bespoke to your requirements. By selecting the options which best suit your needs you can achieve considerable capital savings but you also profit from lifetime cost savings through improved efficiency, high quality and reliability and the safety of your dock leveller.

The 233 with telescopic lip can be extended or retracted by means of a separate control. This operation ensures an ultimately accurate positioning of the dock leveller lip onto the vehicle bed. This ensures you prevent damaging the last load into the vehicle, also referred to as the end load.

The standard load capacities are 60kN or 100kN. However, most load capacity requirements are possible.

During the loading or unloading process the vehicle's upward and downward movement, or float, is automatically followed.

A Loading Systems dock leveller is also suited to load or unload so-called end loads below warehouse level.

The working range or lip angle can be adjusted to suit specific requirements.

A dock leveller can be delivered in almost any RAL colour or hot-galvanised. The working range or lip angle can also be adjusted to suit your specific requirements.

Durability of our dock levellers

The robust construction and self-bearing characteristics facilitate open or closed pit styles or even tailgate openings.

The modular front beam on the lower frame serves to protect the hydraulic and mechanical construction at the bottom of the dock leveller.

The Loading Systems dock levellers include a fully closed hydraulic system.

Safety on and around the dock leveller

The loading bay opening is typically an extremely active egress and ingress logistical opening, so good route planning is essential to manage safety. Loading Systems can increase safety on and around your loading bay openings and can offer you an extensive range of products and accessories.

Low operating hydraulic pressure

The use of one single chrome hardened main cylinder with double sealing ensures that the hydraulic system has an extremely low operating pressure. This reduces failures and increases durability.

Emergency stop facility

Loading Systems has a unique emergency stop safety device integrated into the main cylinder which, unlike most hose rupture valve devices is not temperature sensitive or susceptible to failure.

One single robust main cylinder versus two main cylinders

In an emergency situation, one cylinder will be activated at all times. If a dock leveller emergency stop with two cylinders is activated, these will rarely be activated simultaneously. An unsafe situation could result and the platform could twist.

If your preferred choice is two main cylinders, or if you think two cylinders suits your situation better, then Loading Systems will deliver a dock leveller with two cylinders at no extra cost.

Emergency switch

The control box can be provided with an emergency stop switch with reset protection (panic stop) as an option.

Anti-skid coating

The platform is provided with tear plate as a standard. As an option, the platform can also include an anti-skid coating which also has sound-absorbing properties.

Leveller and door protection

With manual or electrically operated doors, a dock leveller and door protection interlock can be fitted to the dock leveller. This means the dock leveller can only be operated if the door is opened.

Energy-saving & sound insulation

The Loading Systems products are typically located at the interface between the internal and external environments. We are often presented with the challenge of keeping the cold out and the warmth in, or visa versa.

Loading Systems offers a variety of solutions for these requirements. Our control boxes, which can be custom made, play an important part in providing the best solution. Please do not hesitate to ask for information on how we can accommodate the sequential logic of your operational needs into the control box, which can be programmed to suit your needs.

ISO Dock solutions

Our hydraulic dock leveller with a telescopic lip of 1000 mm can be built-in into an ISO-dock layout. This solution allows the industrial door to close in front of the dock leveller, which ensures optimal insulation.

Stepped dock or dock house

For cold storage with refrigerator vehicles or fresh food processing environments where food contamination is a concern, it is important that vehicle doors are only opened after the vehicle is actually docked. We can offer a product solution for this requirement.

Durable draught sealing

Loading Systems has a durable solution to seal even the smallest of gaps between the pit edge and the dock leveller at the sides and at the rear.

Platform insulation

Dock leveller platform insulation not only improves insulation but also provides sound-absorption.

Legislation

Each Loading Systems dock leveller is provided with a CE marking and complies with all safety aspects stipulated in the European Directive EN 1398: 2009. Furthermore, the Loading Systems dock levellers are extensively tested in both real life and simulation software tests.